+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

Laser cutting equipment uses lasers to cut items, so there are certain risks in the operation process, so it is necessary to protect the safety aspects and strictly follow the safety operation regulations, then the laser cutting equipment What are the safe operating procedures? Today, professional laser cutting machine supplier will give you a specific introduction.

1. When using laser cutting equipment, professional personnel are required to operate it. If more than one person is required to operate, then a person in charge must be appointed.

2. When turning on the laser cutting equipment, strictly follow the switch sequence required by regulations. When opening the gas, the exhaust valve of the gas storage tank must be closed first, and then the power supply of the air compressor should be turned on. After the pressure of the air compressor reaches the specified requirements, the valve of the gas delivery pipeline can be opened.

3. When using bottled gas, first open the valve of each bottle, and finally open the main valve switch; when using liquid gas, it is necessary to open the pressure after opening the valve Valve to increase the amount of gasification, thereby ensuring the pressure of the cutting auxiliary gas.

4. When shutting down the laser cutting equipment, make full preparations. First move the cutting head to the highest position, and the other shafts are parked in a safe position. At the same time, the workbench or the exchange workbench should also be stopped in a safe place. Turn off the laser high voltage and laser low voltage first, and then wait three minutes before turning off the laser power supply. Next, turn off the key switch on the laser cabinet and remove it for safekeeping.

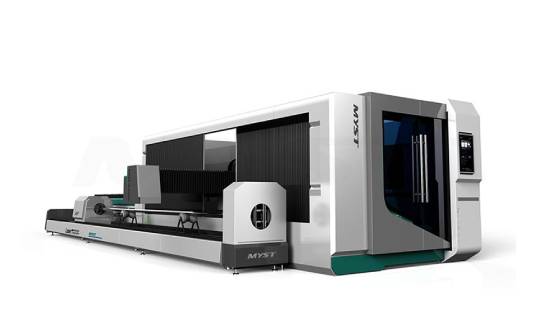

Fiber Laser Metal Cutting Machine

So what factors determine the daily operating experience?

First of all, for laser cutting equipment, it is naturally the laser that is the most important. As the core laser emitting laser, if the quality is not good, it will cause the laser to shift or uneven, which not only affects the cutting effect but also reduces the operating experience. Frequent corrections and operations are required, so when buying such equipment, you should not choose cheap brands, but choose high-quality equipment with good reputation and laser accessories. This is the premise of a good operating experience.

Secondly, when the quality of the laser cutting equipment is guaranteed, the service provided by the manufacturer should also be valued. Usually manufacturers will be responsible for installing and debugging equipment, especially when computer terminal control is needed, they will also help to debug the operation panel, until the daily operation of the user is satisfied, and the knowledge about calibration, debugging and maintenance when using the cutting machine daily as a manufacturer. It will be responsible for training the operator, so that standard operation and maintenance can make the cutting machine run smoothly.

Finally, when the equipment such as Fiber Laser Metal Cutting Machine will also wear normally after a long time, it reflects the service quality of the original manufacturer, and the responsible manufacturer will provide users with It is also very important that the original parts are replaced, and if any problems or cutting machine failures are encountered, the manufacturer will also help solve them as soon as possible.

When operating the laser cutting equipment, everyone must understand the safe operation rules, so as to ensure that no abnormal problems will occur. In particular, it is necessary to pay attention to the order of starting up and shutting down. Once the order is disordered, there may be hidden dangers. In addition, there are friends who need laser cutting equipment, please feel free to contact us.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.