+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

Professional laser cutting machine supplier to share this article for you. In the professional laser cutting machine, for the parts with higher cutting accuracy or thicker thickness, several key technologies must be mastered and solved. Focus position control is one of them. One of the advantages of laser cutting is that the energy density of the beam is high, so the diameter of the focal spot is as small as possible to produce a narrow slit. Because the smaller the focal depth of the focusing lens, the smaller the focal spot diameter. For high-quality cutting, the effective focal depth is also related to the lens diameter and the material being cut. Therefore, it is important to control the position of the focus relative to the surface of the material being cut.

Such a device has its own selection criteria in the middle of the selection process. In fact, once we choose this device, we must determine the production range, and we must make an effective selection according to the processing material or the thickness of the cut. Only in this way can we determine the number of purchased equipment or the relevant machine model, and do the relevant foreshadowing of the subsequent procurement work. How to choose a professional laser cutting machine will have more choices in this regard standard.

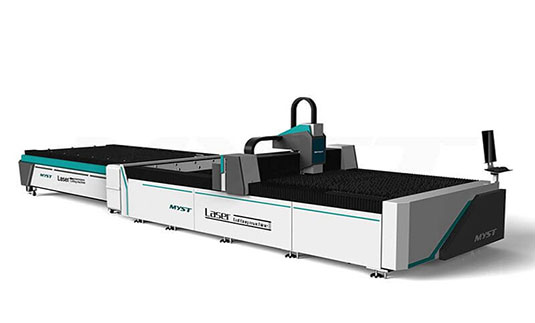

Professional Laser Cutting Machine

1. Fine cutting

When buying, you must also look at their cutting fineness, basically speaking, they can be controlled between 0.1 mm and 0.2 mm.

2. See the deformation of the material

If the laser cutting machine is used for cutting, the material deformation effect of good equipment is very small.

3. The smoothness of cutting surface

In the actual cutting process, the smoothness of the cutting surface is also very important. It is necessary to see if their cutting surface has some burrs. Generally, there will be some burrs, which are basically caused by the thickness of the cutting or The gas used is determined. There is no burr below three millimeters. The gas is good for nitrogen, followed by oxygen. If the air is inside, this effect is also poor. Professional fiber laser cutting machine has relatively few burrs, and it can even be said that the surface without burrs is very smooth.

4. See the power

Most manufacturers have their own power requirements for laser cutting machines and other equipment. From the existing situation, most factories also cut metal plates under six millimeters, and there is no need to buy high-power cutting machines.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.