+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

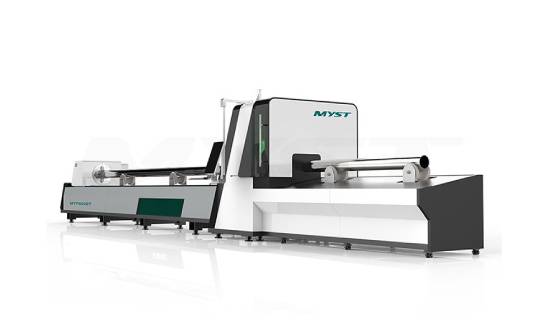

Fiber laser metal cutting machine has become an indispensable tool for metal sheet processing enterprises, its high precision cutting steel plate, high power conversion efficiency and other advantages is the reason why fiber laser cutting machine can quickly occupy the market. Usually, when we use fiber metal laser cutting machine for processing, we occasionally encounter some problems, such as the gap of steel plate cutting is too large, or the accuracy of the processed components is reduced, unable to meet customer requirements and other issues, how to deal with this sudden malfunction? Custom laser cutting machine manufacturer for you to introduce.

1. For various reasons, the surface of the processed object may not be uniform, and a lot of heat will be generated during the processing of the laser cutting machine, which may deform the surface of the thin plate and the surface of the processed workpiece is uneven. The focus of the laser cutting machine and the surface of the processed object randomly change, which will cause the fault of too large cutting gap or inaccurate processing.

2. The error caused by the incorrect installation of the fiber laser cutting machine. The workpiece is placed on the worktable of the metal fiber laser cutting machine. An error will occur due to the incorrect position of the worktable. The equipment is not installed firmly, the parts are worn for a long time, and the worktable surface will also be unevenly stressed. This imbalance will also produce random errors between the thin steel plate and the laser focus, resulting in excessive cutting gaps or reduced processing accuracy.

3. Errors caused by programming. During the processing of the fiber laser cutting machine, the complex workpiece surface processing path map is composed of many models such as straight lines and arcs. It needs to be drawn using professional software. Some software programming systems also include There are some errors, and the use of genuine software can avoid these errors to the greatest extent.

4. The occurrence of the focus position error in laser cutting. During the processing of the fiber laser cutting machine, there are many factors that lead to the change of the relative position of the focus and surface of the cutting object. For these random errors can not be avoided, only through online detection and control to reduce the error, so as to ensure the processing accuracy of the fiber laser cutting machine.

5. Regularly check whether there is a problem with the focal length of the fiber laser cutting machine, especially after cleaning the lens or better new lens.

6. Check whether the lens of the metal fiber laser cutting machine is damaged or contaminated, because these problems will cause laser scattering, resulting in too large cutting gaps or reduced processing accuracy of the laser cutting machine, timely replacement or cleaning of the lens is an effective solution.

7. The quality of the laser tube is also a factor that cannot be ignored. Check the quality of the laser spot. If there are bright spots or spots that are not round or hollow, the solution is to adjust the support, rotation direction, or replace the laser tube.

All in all, fiber laser metal cutting machine china often has some failures during use. The most common impact of these failures is to reduce the processing accuracy or cause the cutting gap to be too large. These conditions will affect the production of the enterprise. Cause adverse effects, or produce unnecessary waste. This requires us to do a good job of equipment maintenance in our daily work to ensure the efficient and lasting operation of the laser cutting machine, and let the fiber laser cutting machine create maximum value for the enterprise.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.