+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

Fiber laser cutting machine CNC is widely used in all walks of life. As an important part of the fuselage, the gantry has a great impact on the efficiency, accuracy, and stability of the metal cutting laser machine, and it has attracted more and more attention. So what is the type and applicable power of the gantry of the metal fiber laser cutting machine? MYST Laser takes you to find out.

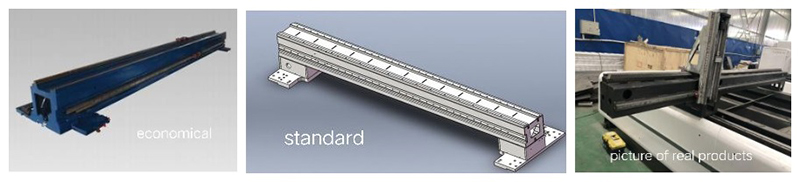

There are currently four main gantries of machines for laser cutting of metal: manganese steel gantry, aluminum profile gantry, aluminum cast gantry, and aviation aluminum gantry.

1. Manganese steel gantry: high requirements for welding and heat treatment at various stages. The large cross-sectional size of the gantry and the thick steel plate used to lead to the excessive weight of the gantry and poor dynamic response, which indirectly leads to an increase in the selection of drive motors and increases the cost of fiber laser cutting machine for metal.

2. Aluminum profile gantry: reasonable cross-section and strength can be obtained, but the welding deformation is large, the manufacturing cycle is long, and it is only used for single-piece, small-batch production.

3. Aluminum cast gantry: This gantry is currently used by most manufacturers of CNC metal laser cutting machine, but it is limited by the requirements of fluidity during casting, the mechanical properties of the material are poor, and the weight of the gantry is difficult to continue to reduce.

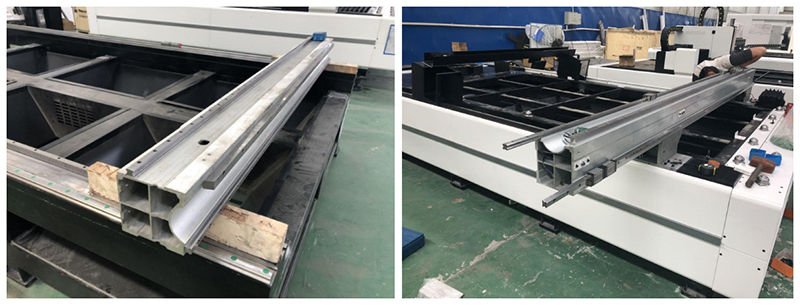

4. Aviation aluminum gantry: The gantry adopts a new structure, the fiber laser cutting machine sheet metal gantry extruded from aluminum profiles, which solves the poor mechanical properties of the previous gantries in the production and application of the gantry, many casting defects, and welding deformation. Large, long manufacturing cycle, only used for a series of problems such as single piece and small batch production. This type of gantry is currently the most widely used gantry on the market.

Advantages of aviation aluminum gantry:

1. Fine processing after the extrusion molding process and quenching heat aging process makes the overall rigidity and surface quality of the gantry very good, and at the same time has good toughness and ductility.

2. Based on the metal characteristics of aluminum alloy, corrosion resistance, lightweight, high rigidity, it guarantees the high-speed movement of CNC laser cutting machine fiber processing and has the perfect dynamic performance. Under the condition of meeting the accuracy, it can achieve high-speed of various graphics Cutting.

3. Long service life, which can keep the shape unchanged to the greatest extent, so as to ensure cutting accuracy and product quality

MYST Laser’s cutting laser machine metal uses a brand new cast aluminum gantry: It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, lightweight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.