+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

The science class of MYST Laser has started. Today we will learn about the lathe bed part of the CNC laser cutting machine metal.

The machine lathe bed of the CNC laser fiber optic cutting machine steel needs to bear the entire weight of the entire machine and the processing materials, and mainly plays the role of load-bearing support. It plays the same role as the foundation of the building. If the foundation is not strong, the appearance of the house will collapse no matter how good it looks; The machine lathe bed quality of the CNC fiber laser cutting machine metal is not up to standard, and the machine lathe bed will also be deformed, resulting in the deformation of the rail, rack, and gantry, which affects the cutting accuracy of the machine, makes the machine unable to work normally, and also affects the service life of the whole machine.

The lathe bed of mainstream laser fiber cutting machine on the market is generally divided into two types: iron cast machine lathe bed (one-piece construction) and welded machine lathe bed (tube-sheet welding).

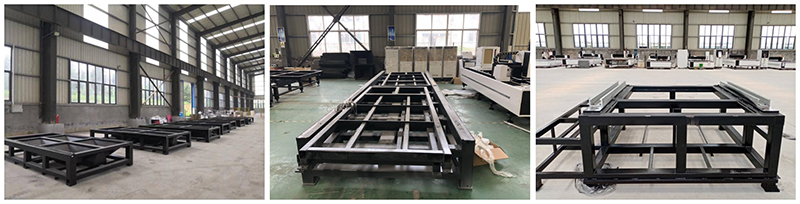

The iron cast machine frame is habitually called a one-piece iron cast machine frame in the industry. It is made of flake graphite cast iron with a minimum tensile strength of 200MPa as the raw material and is cast at a high temperature as a whole. After multiple strict thermal aging and natural aging, it forms a bed matrix with ultra-high stability.

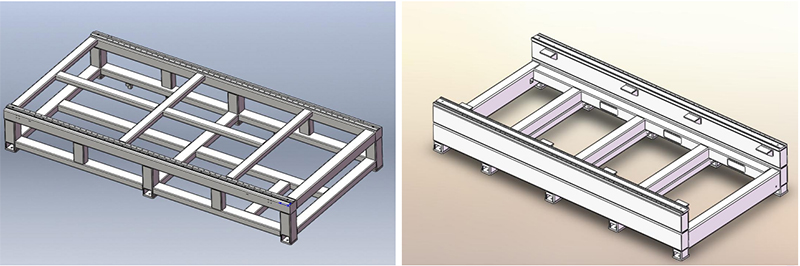

The body of the metal cutting fiber laser machine tool with a welded structure is welded by steel plates as the name implies. During the welding process, the local structure of the material changes, and due to the heating of the whole part, the uneven force of the force, resulting in serious material and structural stress. After the strict heat treatment process, it still cannot be completely eliminated, resulting in the inevitable slight fluctuation of the linear accuracy of the machine tool in the process of processing, assembling, and using. According to the different welding materials of the bed, the bed can be divided into two types: metal tube welded machine lathe bed and a metal plate welded machine lathe bed.

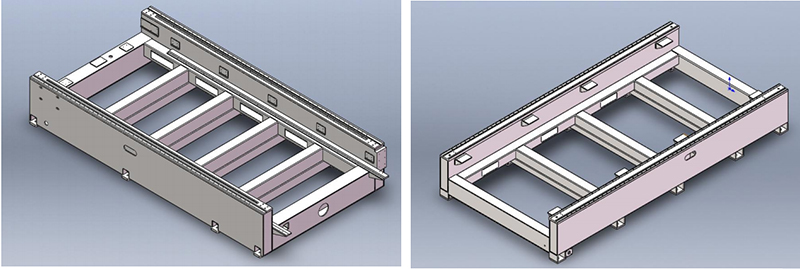

The metal tube welded machine lathe bed is made by welding metal square tubes one by one. The advantage is that the manufacturing process is simple, the cost is low, and the disadvantage is that it is easy to deform, and the laser cutting machine is prone to resonance when running at high speed, which causes the bed to shake and affect cutting accuracy is generally suitable for low-power laser cutting machine sheet metal.

The Metal plate welded machine lathe bed is supported by two steel plates with a thickness of 16-22mm, and cross-reinforced ribs are added inside, which is firm and not easy to deform. Because of the unique welding structure, it can quickly dissipate the force during the movement, so as to achieve a better shock absorption effect, which can effectively reduce the error caused by the vibration during the cutting process, making the cutting more accurate, suitable for high power laser cutting machine(above 4000W).

The steel sheet cutting machine laser produced by our company can be equipped with a cast iron bed or welding bed according to the machine model and customer needs. Below 4000W, we are the standard metal tube welded machine lathe bed. Customers can add money to choose the metal plate welded machine lathe bed. If customers choose exchange table fiber laser cutting machine and high power laser cutting machine (4000W and above ), the bed must be a Metal plate welded machine lathe bed with higher stability and accuracy.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.