+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

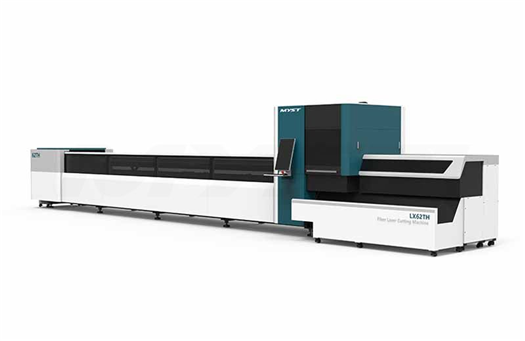

Nowadays, CNC laser metal cutters on the market have been fully popularized. Tube laser cutting machines are used for precision processing and cutting of metal round tubes and square tubes. Let’s take a look today at what are the advantages of laser tube cutting machines in processing and cutting round tubes? What are the application cases? What are the advantages of a laser cutting machine for metal tubes? Let me introduce you one by one.

Processing characteristics of fiber laser tube cutting machine:

1. There are many types of cutting pipes, which can cut round pipes, square pipes, flat pipes and other materials, such as cutting, perforating, hollowing out the pipe wall, and beveling and other three-dimensional processing.

2. The laser processing speed is fast and the cutting precision is high, which can realize high-efficiency processing in large quantities.

3. The operation is simple; use the CNC operating platform and input the corresponding drawings to realize fast processing, flexible and fast.

Application cases of tube laser cutting machine:

1. Oil screen

Pipe laser cutting machine processing oil screen accuracy: screen wall thickness ≤ 20mm, slit width ≥ 0.15mm, slit cross-sections are rectangular, trapezoidal and various special-shaped holes. The types of slits include parallel, staggered, spiral, etc., and the center of the hole The distance error is 0.01-0.02 mm, the positioning accuracy of the density laser beam is ±0.03mm, the repeatability is ±0.01mm, and the surface cutting finish is 6.3.

2. Lighting lamps

The common styles of metal lamp covers are hollow carved patterns, and even more complicated patterns. The tube laser cutting machine has high efficiency in processing the lamp housing, the pattern is clear and does not deform, and no secondary processing is required, which greatly reduces the production cost.

3. Automobile exhaust pipes

As a high-end consumer product, the production process of the product is the main breakthrough point in order to enhance the value of the product. The laser cutting machine for tube steel processes automobile exhaust pipes without burrs, the inner tube wall is smooth, and the processing speed is fast. It is a good choice for batch processing.

Introduction of advantages:

1. Automatic cutting and blanking; the laser pipe cutting machine adopts a dual-drive pneumatic chuck rotation structure (active shaft and driven shaft), the active shaft starts the chuck to clamp the tube and fix it, and then the tube is carried out by the three-dimensional movement of the machine For cutting processing, the driven shaft starts the chuck to move along the workpiece axis with the worktable, and the automatic cutting and blanking function of the metal pipe can be seen.

2. Numerical control cutting technology; the cutting control software that comes with the CNC laser pipe cutting machine provides advanced cutting technology and rich cutting experience so that cutting operators can achieve high-quality and high-efficiency CNC cutting through the skilled use of the control system.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.