+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

Laser cutting machine technology uses the energy released when the laser beam is irradiated to the surface of the metal sheet. The metal sheet is melted and the molten slag is blown away by the gas. Because the laser power is very concentrated, only a small amount of heat is transferred to other parts of the metal sheet, causing little or no deformation. The laser can be used to cut blanks with complex shapes very accurately, and the cut blanks do not need to be further processed.

The laser source generally uses a carbon dioxide laser beam with an operating power of 500 to 5000 watts. This level of power is lower than the power required by many domestic electric heaters. Due to the lens and reflector, the laser beam is concentrated in a small area. The high concentration of energy enables rapid local heating to melt the metal sheet.

A metal cutting machine can cut stainless steel up to 16mm, and adding oxygen to the laser beam can cut 8-10mm thick stainless steel. However, after oxygen cutting, a thin oxide film will be formed on the cutting surface. The maximum thickness of the cutting can be increased to 16mm, but the size error of the cutting part is large.

As a high-tech laser technology, since its inception, it has been developing laser products suitable for various industries, such as laser printers, laser beauty machines, laser marking CNC laser cutting machines, laser cutting machines, etc., for different social needs. The CNC laser cutting machine price is favorable, the quality is perfect, and it has received great praise.

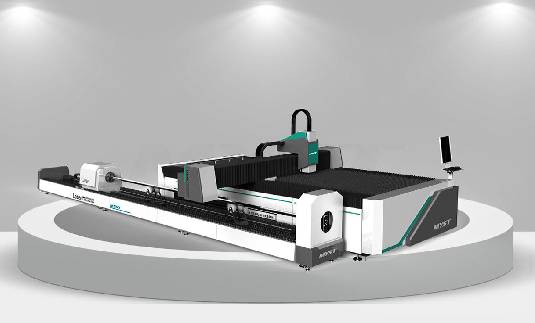

Metal Cutting Machine

Laser cutting machine principle-principle

In the laser cutting machine, the main work is the laser tube, so we have to understand the laser tube.

We all know the importance of laser tubes in laser equipment clearly. The following is the most common type of laser tube.

The composition of the laser tube is made of hard glass, so it is a fragile and fragile substance. To understand the CO2 laser tube, we must first understand the structure of the laser tube, like this carbon dioxide laser uses a layered sleeve structure, the most inside is a layer of the discharge tube. However, the diameter of the carbon dioxide laser discharge tube is thicker than the laser tube itself. The thickness of the discharge tube is proportional to the diffraction reaction caused by the size of the spot. The length of the tube and the output power of the discharge tube also form a Species ratio.

During the operation of the laser cutting machine, the laser tube will generate a lot of heat, which affects the normal operation of the cutting machine. Therefore, a special water chiller is required to cool the laser tube to ensure that the laser cutting machine works normally at a constant temperature.

Laser cutting machine is a cutting technology that uses laser characteristics and lens focusing to concentrate energy to melt or vaporize the surface of the material. It can achieve the advantages of good cutting quality, fast speed, many cutting materials and high efficiency.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.