+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de tecnología

Casa >> Blog >> Noticias de tecnología

In recent years, the wide application of CNC steel laser cutter has benefited from the rapid development of the sheet metal industry. Laser iron cutting machine has the characteristics of fast cutting speed, good cutting effect, and long service life, and has been sought after by the metal processing industry. Many customers who are interested in buying but don’t know much about CNC laser metal cutters will eagerly want to know how to choose an excellent stainless steel laser cutting machine. Today, MYST Laser will answer questions for customers with problems in this area. Everyone clearly knows what characteristics a metal sheet laser cutting machine should satisfy customers.

1. The core technology of the equipment is advanced.

The core technology of steel laser cutter is the design of its machine tool, laser, cutting head, chiller and other core components. Leading and mature technical support is the key to producing an excellent fiber laser cutting machine.

2. The equipment structure design is reasonable.

The steel laser cutter machine is composed of a light path system, air path system, cooling system, transmission system, electric control system, and operating system. The reasonable and applicable structural design can make the production process more convenient, such as loading, unloading, and Maintenance etc.

3, the equipment failure rate is low and the quality is reliable.

The structure of the CNC laser metal cutter is very complicated. To ensure the reliable quality of the equipment, the design must be reasonable. The quality of the materials used and the quality of various parts are very important. The key parts of the fiber laser cutting machine are all world-class accessories. Quality can ensure that the fiber laser cutting machine will not have any failures during the working process, so it can effectively improve the work efficiency and extend the service life.

4, the equipment runs stably and the processing effect is good.

High-quality 3d fiber laser cutting machine will use better machine tools and transmission components, so it can effectively ensure the smooth operation of fiber laser cutting machines. During the operation, there will be no abnormal vibrations and no noise. The fiber laser cutting machine uses a laser beam to cut various metal materials. The cutting speed is fast, the cutting section is smooth, and the cutting effect is good.

5, high precision

To a large extent, cutting accuracy has become a standard for measuring the quality of a laser for cutting metal machine. There are many factors that affect the accuracy of laser cutting. Of course, there are factors of the equipment itself. At the same time, the accuracy also has a certain impact on the accuracy of the laser cutting machine with the cutting materials and materials.

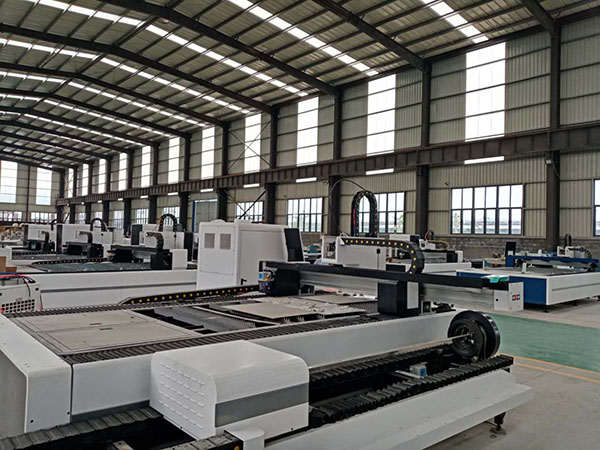

MYST Laser is a manufacturer specializing in the development and production of sheet metal laser cutting machines. We only produce equipment that satisfies customers. The above-mentioned core technology is advanced, the structure design is reasonable, the failure rate is low, the quality is reliable, the operation is stable, the processing effect is good, and the precision is high. Our laser cutting machines for the metal have the five characteristics, the quality is guaranteed, and customers who are interested in buying can buy with confidence.

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.