+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

+86 132 5674 2787

Máquina de corte por láser de metal, Máquina de corte por láser de fibra, Proveedor de máquinas de corte por láser, Máquina de marcado láser, Máquina de marcado láser de fibra...

Noticias de la compañía

Casa >> Blog >> Noticias de la compañía

How laser cutting machine works?

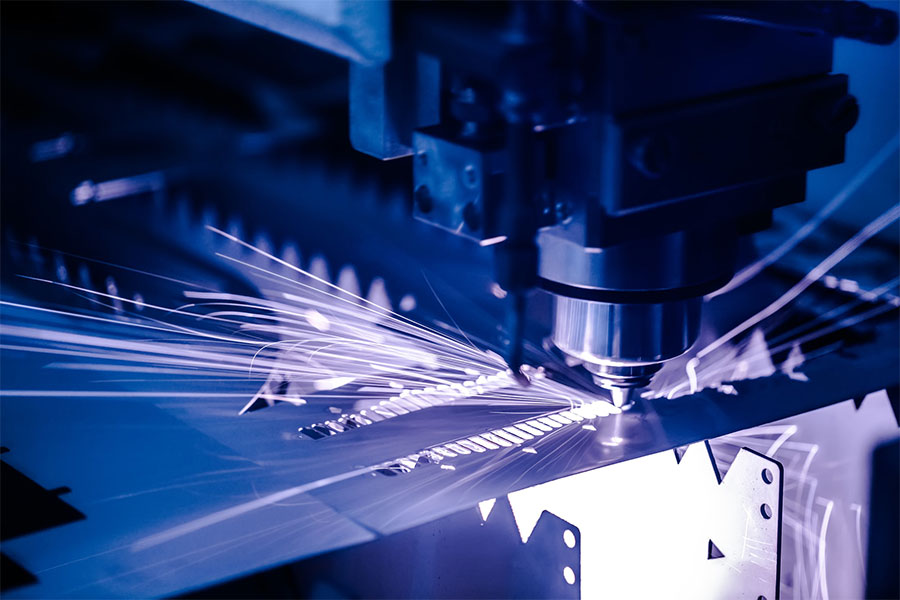

The laser cutting is irradiating a high-energy-density laser beam on the surface of the workpiece, and the irradiated area is instantaneously melted or vaporized while the molten material is blown off by the high-speed airflow, thereby cutting the workpiece.

The advantages of laser cutting compared with other cutting methods are as follows:

1. High cutting precision

Due to the small laser spot and high energy density, the cutting speed is very high. The laser cutting precision is very high. The cutting part has a dimensional accuracy of ±0.04mm. The cutting surface is very smooth. The surface roughness is only a few tens of micrometers. In many cases, the parts can be directly used without other machining. Another very big advantage is that the laser-cut heat affected zone is very small and the workpiece is almost free of distortion, which is unmatched by other hot-cutting processes.

The cutting accuracy is actually the core point of the difference between different manufacturers. Why does the cutting machine produced by MSTY laser have very high precision?

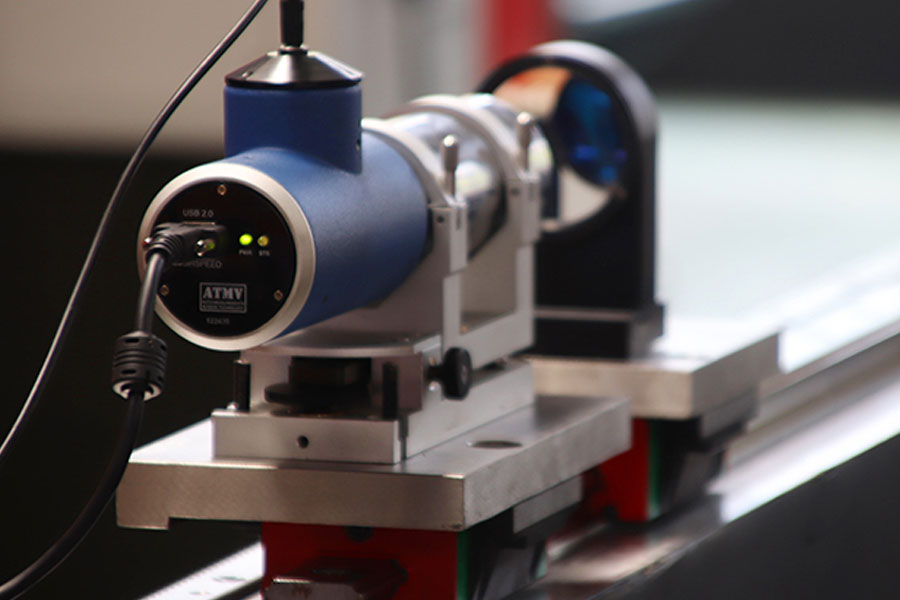

In general, the impact of cutting effect and accuracy are mainly the following aspects: 1. Laser focusing spot size 2. Workbench positioning accuracy 3. Workpiece thickness 4. Workpiece material. The smaller the laser focusing spot, the higher the table positioning accuracy, and the thinner the workpiece thickness, the higher the accuracy. The thickness of the workpiece and the material of the workpiece according to the customer's work, so it is not the core of our control of cutting precision. Therefore, we need to control the cutting accuracy from the laser focused spot size and the positional accuracy of the table.

The adjustment of the laser focus spot size adjustment is mainly the accurate control of the focus. The smaller the focal depth of the focusing lens, the smaller the spot size at the focus, and the control of the cutting position by controlling the focus position on the metal surface. Secondly, adjusting the cutting and perforating process is also a core point of precision adjustment. The laser cutting machine is a hot cut, which needs to first penetrate a small hole in the metal sheet, and then the laser cuts the sheet from the small hole. Third, the airflow control in the process of machining the workpiece by the laser cutting machine, the oxygen or nitrogen is pressed by the nozzle and the laser beam acts on the surface of the material to be cut. The basic requirement for the airflow is that the flow rate is large and the speed is fast, and there is guaranteed Sufficient air flow blows away the slag.

2. Easy to realize 2D cutting and 3D cutting

Laser cutting can be configured with a non-empty control program. The cutting process is numerically controlled. Only two different cutting software can be selected to realize two-dimensional cutting and three-dimensional cutting. Regarding the fiber cutting machine cutting system, the best cutting machine software is Shanghai Cuycut. Cutting system, founded on September 11, 2007 in Zizhu National High-tech Industrial Development Zone, is a high-tech private enterprise. Shanghai Cupcut cutting system has simple operation and stable performance with almost zero failure rate. At present, the most commonly used system models mainly include FSCUT1000. FSCUT2000, FSCUT3000, FSCUT3000S, FSCUT4000S, FSCUT5000, FSCUT8000.

3. Fast cutting speed: fiber cutting speed, MYST cutting machine idling speed up to 120m / min cutting speed can also be up to 60m / min machine acceleration reaches 1.2G. Greatly improve the efficiency of production and processing.

4. Non-contact cutting: The laser head has no contact with the workpiece during laser cutting. To machine parts of different shapes, simply change the laser processing path of the laser. Therefore, the laser cutting process has low noise and low vibration.

5. The machine is low in cost and maintenance-free: the photoelectric conversion rate of fiber cutting is up to 30%, which greatly saves power consumption. In addition, the machine has a low failure rate and is maintenance-free, which greatly saves the cost of use.

Ninguno

Análisis de los factores que afectan la calidad del corte por láser y cómo controlarlo

En comparación con el método de corte tradicional, el corte por láser tiene ...

Campos de aplicación de la máquina de corte por láser de fibra

Las máquinas de corte por láser de fibra se están volviendo populares gradua...

Cómo mantener una máquina de corte por láser de fibra

Los dueños de los talleres de fabricación de metales tienen muchas cosas a ma...

+86 132 5674 2787

Dirección: Habitación 2309, Edificio 3, Bloque Lvdi Ruili, Distrito de Shizhong, Ciudad de Jinan, Provincia de Shandong, China.